Capabilities

Cartor’s security certifications make it possible to procure a broad range of security components including reactive or machine detectable inks, holograms, and security threads. However, it is our knowledge that enables us to expertly combine these components and incorporate specialist techniques such as microtext, guilloche, or rainbow print to convert them into high quality finished products.

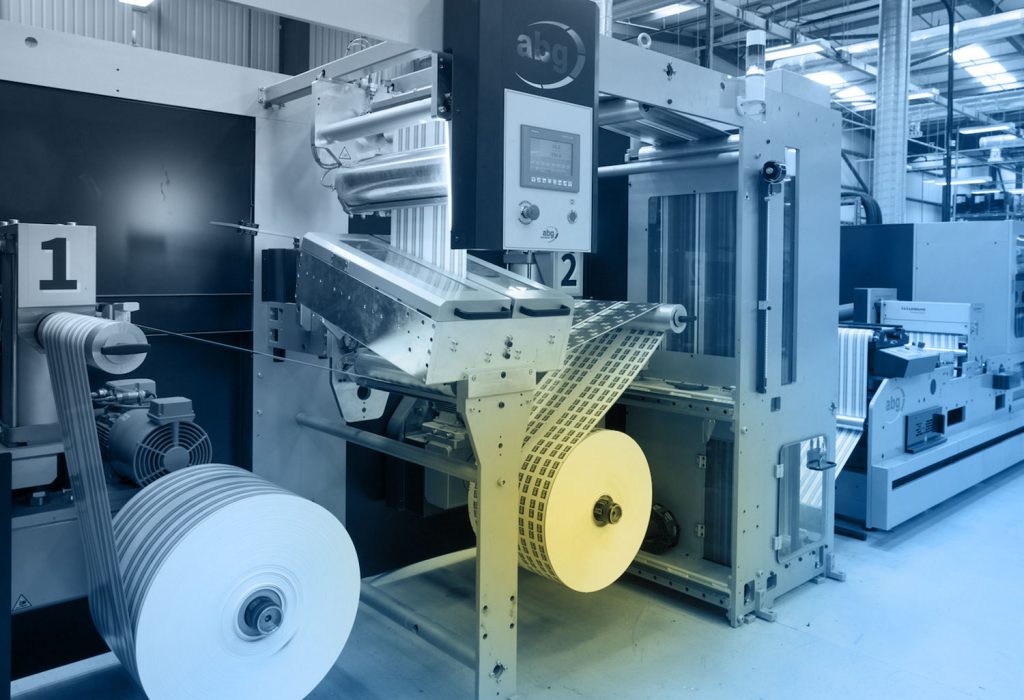

Investment in digital, offset, and gravure presses, in addition to silk screen and flexographic units enables us to fulfil the most challenging technical and aesthetical requirements whilst sheet and reel fed combinations ensure print layouts are optimised for all volumes whether it’s short-run bespoke jobs or high-volume contract work.

High calibre ink jet heads in both black and colour have been strategically placed on finishing equipment to enable the seamless application of variable data to a range of products. Options exist for customers to supply their own data or have our in-house experts manage it for them using bespoke software that generates data in various formats and with different levels of encryption depending on requirements.

Cartor’s finishing capabilities are at the forefront of the security printing industry and encompass a wide variety of operations including die cutting, chopping out, matrix stripping, coiling, and sheeting. In addition to this, Cartor can apply registered holograms in sheet or reel format as well as emboss, foil and perforate.

In the security printing industry, it is extremely important to ensure each stock keeping unit contains the exact number of products required, especially when dealing with legal tender or high monetary value products. To ensure this, a range of bespoke counting, collating, and packing machinery (banding, wrapping, folding) has been installed along with automatic high resolution inspection systems which, when combined, all but remove the risk of miscounts or quality issues.

Although Cartor has invested heavily in automation, there are some jobs that simply can’t be done on a machine. For this work, we have a team of experienced staff dedicated to hand-finishing and assembly. This same department is also responsible for providing a pick and pack service to several major postal administrations and achieves industry leading performance standards in terms of accuracy and timeliness.

Cartor has developed the capability to print on a range of substrates including polymers for high-security markets, such as currency and ID.

Our acquisition by Spectra has cemented the group’s position as a [serious] polymer banknote substrate supplier. The Group’s Fusion™ polymer banknote substrates meet or exceed industry metrics for physical properties, printability and hazard resistance. Fusion is available with or without covert, level III security and is produced in print-ready sheet form to specific central bank specifications including print layout and clear window design. The level III security feature is embedded in the Fusion substrate, which provides the highest level of protection against counterfeiters who have easy access to commercial BOPP film. Spectra’s proprietary security taggant and manufacturing process ensure high window clarity and enable high-speed authentication on banknote processing machines.

In the ID segment, polycarbonate is increasingly the substrate of choice for passports due to its superior durability, transparency, and low moisture absorption, but other materials are used for different ID solutions, such as Teslin or PET / PVC. We can apply or embed a variety of security features onto and into substrates like these including secure inks and designs, taggants and holographic foils, all in excellent register and according to bespoke design requirements.